How to deal with the abnormal shedding of electrostatic powder coating on small steel wheels?

How to deal with the abnormal shedding of electrostatic powder coating on small steel wheels?

Abnormal shedding of electrostatic powder coating on small steel wheels is often caused by issues in the pretreatment, powder coating, or curing process. Below is a structured troubleshooting guide to help you identify and resolve the issue:

—

## 🔎 1. **Check Pretreatment / Surface Preparation**

Powder coating adhesion relies heavily on good surface preparation. Common issues:

– **Incomplete degreasing or oil residue** — leftover oils block adhesion.

– **Insufficient phosphate or conversion coating** — poor chemical pretreatment weakens bonding.

– **Rust or mill scale not fully removed** — coating adheres poorly to contaminated metal.

– **Drying process too fast or too slow** — moisture trapped under the powder causes adhesion failure.

### ✔ Solutions:

– Review degreasing bath concentration and temperature.

– Check phosphate or conversion coating thickness (typically 1-2 g/m²).

– Inspect for rust or contamination after pretreatment.

– Ensure complete drying before powder application.

—

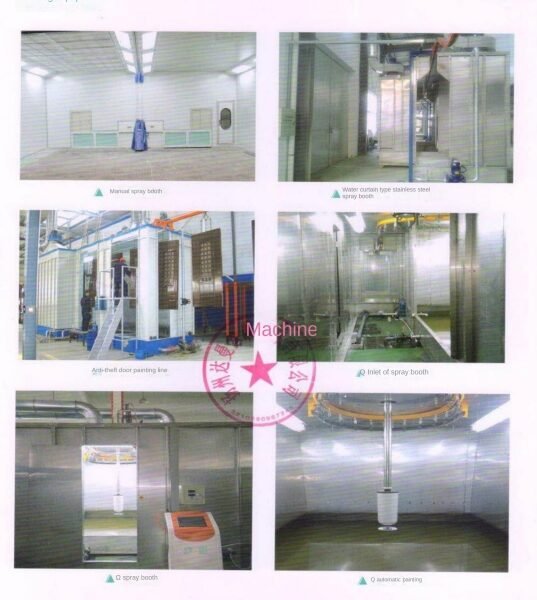

## 🔎 2. **Electrostatic Spraying Process Issues**

Poor powder deposition leads to weak spots prone to shedding.

### Common problems:

– **Incorrect grounding of the wheel or hooks** — weak electrostatic attraction.

– **Low powder charge (kV setting too low) or high current** — insufficient wrap-around.

– **Powder too humid or clumped** — poor fluidization affects spray uniformity.

– **Air pressure too high or low** — uneven powder distribution.

– **Faraday cage effect in crevices or corners** — powder fails to deposit in tight areas.

### ✔ Solutions:

– Ensure grounding resistance < 1 MΩ.

– Set appropriate voltage (60–90 kV for small steel parts).

– Store powder in dry conditions, ensure proper fluidization.

– Adjust spray gun distance (15-30 cm).

– Use touch-up spraying on deep corners or switch to tribo guns if needed.

—

## 🔎 3. **Curing Process (Critical for Adhesion)**

If powder isn’t fully cured, the coating can easily flake or shed.

### Common issues:

– **Undercuring** — oven temperature too low or time too short.

– **Overcuring** — degrades adhesion or makes the coating brittle.

– **Uneven temperature inside the oven** — inconsistent curing on small wheels.

### ✔ Solutions:

– Check oven temperature profile with a data logger.

– Ensure curing matches powder specs (e.g., 180-200°C for 15-20 min metal temp).

– Verify wheel metal temperature, not just air temp.

– Avoid stacking that creates cold spots.

—

## 🔎 4. **Powder Quality or Incompatibility**

– Using low-quality powder or incompatible powder types can cause poor adhesion.

– **Recycled powder ratio too high** — can reduce performance.

### ✔ Solutions:

– Use fresh powder within shelf life.

– Keep reclaimed powder ratio below 20-30%.

– Verify powder is formulated for steel wheels (epoxy/polyester blend if needed).

—

## 🔎 5. **Mechanical Handling / Damage**

– Powder shedding might be due to damage **after** coating during handling, stacking, or transport.

### ✔ Solutions:

– Review handling process post-curing.

– Use softer materials to separate wheels and reduce mechanical stress.

—

## ✅ Summary of Action Plan:

| Issue Area | Check / Fix |

|——————–|—————————————————————|

| Pretreatment | Cleanliness, rust removal, proper phosphating |

| Powder Application | Grounding, powder fluidization, Faraday issues, correct kV |

| Curing | Correct temperature/time, avoid cold spots |

| Powder Quality | Fresh, compatible powder, low recycled ratio |

| Handling | Minimize post-cure mechanical damage |

—

Would you like help creating a checklist or troubleshooting flowchart for your production line? Or do you want specific advice based on your process setup (manual/auto line, wheel size, powder type)?

electrostatic powder coating technician

electrostatic powder coating technician jobs

electrostatic powder coating technology

electrostatic powder coating theory

electrostatic powder coating thickness

electrostatic powder coating voltage

electrostatic powder coating vs powder coating

electrostatic powder coating wikipedia

electrostatic powder coating without baking

electrostatic powder coating without making

electrostatic powder coatings