Choosing a powder coating oven is a critical decision for businesses involved in the finishing industry, whether you’re a small-scale operation or a large manufacturing enterprise. The right oven can significantly impact the quality of your finishes, operational efficiency, and overall productivity. This article will guide you through the key factors to consider when selecting a powder coating oven, ensuring you make an informed decision that meets your specific needs.

—

## Understanding Powder Coating Ovens

### What is a Powder Coating Oven?

A powder coating oven is a specialized piece of equipment used to cure powder-coated items. After a part is coated with powder, it is placed inside the oven where the powder melts, flows, and forms a hard, durable finish. The process requires precise temperature control and even heat distribution to ensure a high-quality finish.

### Types of Powder Coating Ovens

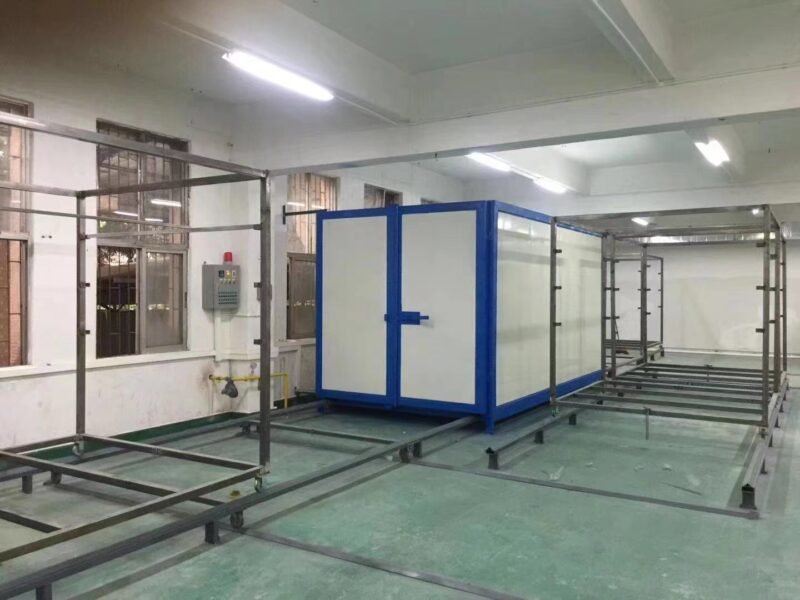

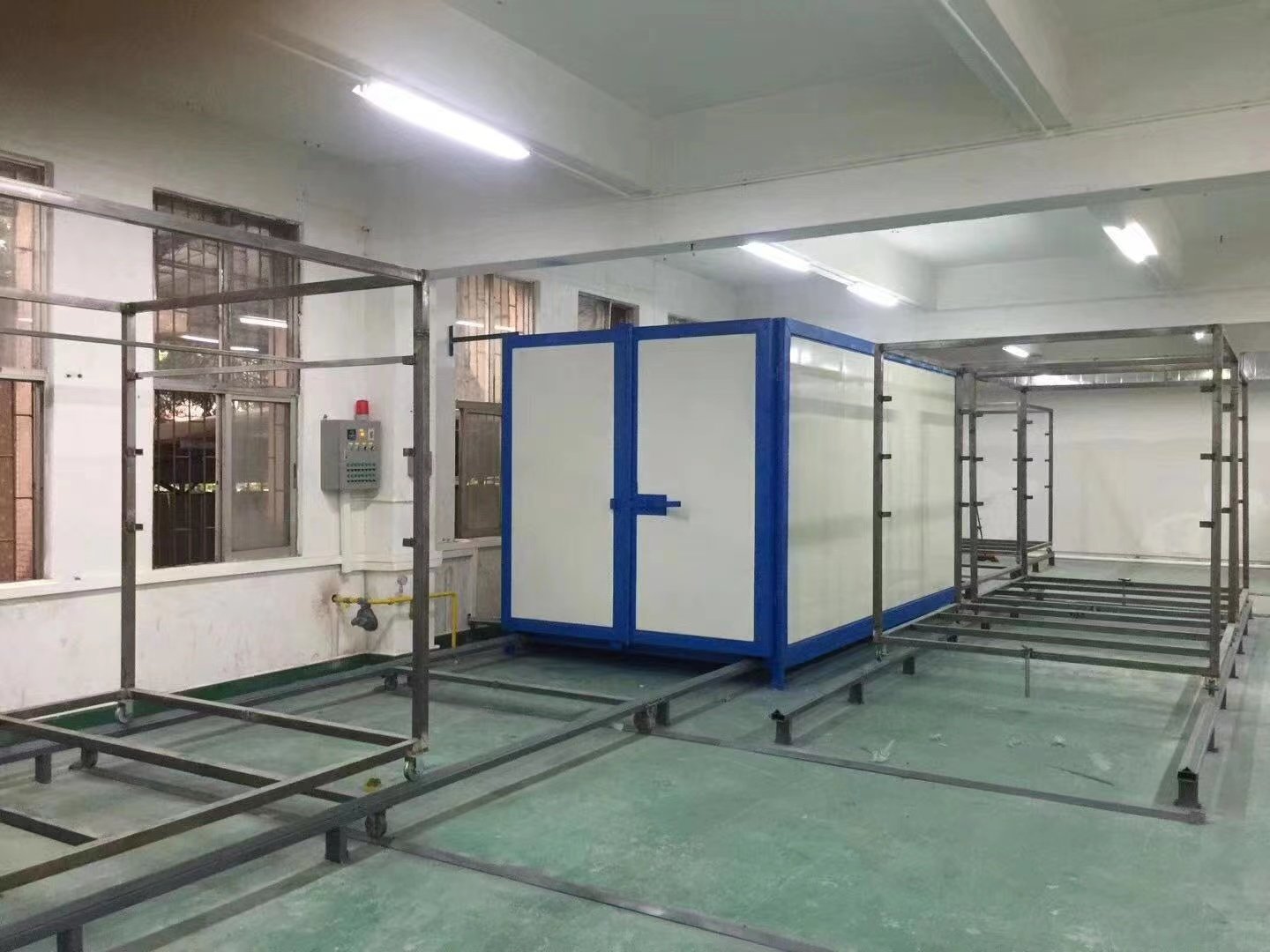

1. **Batch Ovens**: Ideal for small to medium operations, batch ovens are used for curing small to medium-sized parts. They allow for flexibility in part size and volume but may not be as efficient for high-volume production.

2. **Conveyor Ovens**: Best suited for large-scale manufacturing, conveyor ovens facilitate continuous production. Parts are loaded onto a conveyor system that moves through the oven, allowing for efficient high-volume processing.

3. **Walk-In Ovens**: These are larger batch ovens designed to accommodate oversized or heavy parts that require manual loading and unloading.

4. **Box Ovens**: Similar to batch ovens, box ovens are suitable for small to medium workloads and can accommodate parts that vary in size.

—

## Factors to Consider When Choosing a Powder Coating Oven

### 1. **Size and Capacity**

– **Assess Your Needs**: Evaluate the size and volume of the parts you intend to cure. Ensure the oven can accommodate the largest parts you’ll be working with, including considering the space needed for racks or fixtures.

– **Future Growth**: Consider your business’s future growth. It might be more cost-effective to invest in a slightly larger oven than you currently need to accommodate potential increases in workload.

### 2. **Type of Oven**

– **Batch vs. Conveyor**: Choose between a batch oven for flexibility and smaller runs or a conveyor oven for high-volume, continuous production. Your choice should align with your production process and output requirements.

### 3. **Heating Method**

– **Electric vs. Gas**: Decide between electric and gas-powered ovens. Electric ovens are generally more precise and easier to maintain, while gas ovens tend to have lower operating costs and faster heating times.

### 4. **Temperature Uniformity**

– **Consistent Curing**: Uniform temperature distribution is crucial for consistent curing and high-quality finishes. Look for ovens with advanced airflow design and efficient heat distribution mechanisms.

### 5. **Energy Efficiency**

– **Operating Costs**: Consider the energy consumption of the oven. Energy-efficient models may have a higher upfront cost but can significantly reduce operating expenses over time.

### 6. **Control System**

– **Ease of Use**: Look for an oven with an intuitive control system that allows precise temperature control and easy programming for different curing cycles.

– **Automation Options**: Consider ovens with advanced automation features if you require consistent production with minimal manual intervention.

### 7. **Safety Features**

– **Safety First**: Ensure the oven has essential safety features such as over-temperature protection, proper ventilation, and emergency shut-off mechanisms.

### 8. **Quality and Brand Reputation**

– **Manufacturer’s Track Record**: Research the manufacturer’s reputation and read reviews from other users. Reliable brands often offer better support, warranties, and long-term reliability.

### 9. **Cost and Budget**

– **Investment vs. Return**: Consider both the initial cost and the long-term value of the oven. A more expensive, high-quality oven may offer better performance and durability, providing a better return on investment.

—

## Additional Considerations

### 1. **Space and Installation Requirements**

– **Facility Layout**: Consider the available space in your facility. Ensure the oven fits comfortably and that there’s adequate room for loading, unloading, and maintenance.

– **Ventilation**: Proper ventilation is crucial for safety and efficiency. Ensure your facility can accommodate the ventilation requirements of your chosen oven.

### 2. **Maintenance and Support**

– **Ease of Maintenance**: Choose an oven with accessible components for easy maintenance and repairs. Regular maintenance is essential for optimal performance and longevity.

– **Technical Support**: Opt for manufacturers that offer robust customer support and readily available spare parts.

### 3. **Environmental Considerations**

– **Compliance**: Ensure the oven meets all relevant environmental regulations and standards. Some regions may have specific requirements for emissions and energy consumption.

### 4. **Customization Options**

– **Tailored Solutions**: Some manufacturers offer customization options to tailor the oven to your specific needs. This can include special racks, doors, or additional features that enhance functionality.

—

## Conclusion

Choosing the right powder coating oven requires careful consideration of your production needs, budget, and facility constraints. By evaluating the factors outlined in this guide, you can make an informed decision that aligns with your business goals and enhances your powder coating operations. Remember, investing in the right equipment is essential for achieving high-quality finishes, improving efficiency, and ensuring long-term success in the powder coating industry.

Whether you’re upgrading your current setup or starting a new operation, take the time to research and consult with experts to find the best powder coating oven for your specific needs.