How to distinguish the quality of electrostatic spray powder?

How to distinguish the quality of electrostatic spray powder?

Distinguishing the **quality** of **electrostatic spray powder** is crucial to ensure **durability, adhesion, and appearance** in powder coating applications. Here are key ways to evaluate its quality:

### **1. Visual Inspection & Physical Properties**

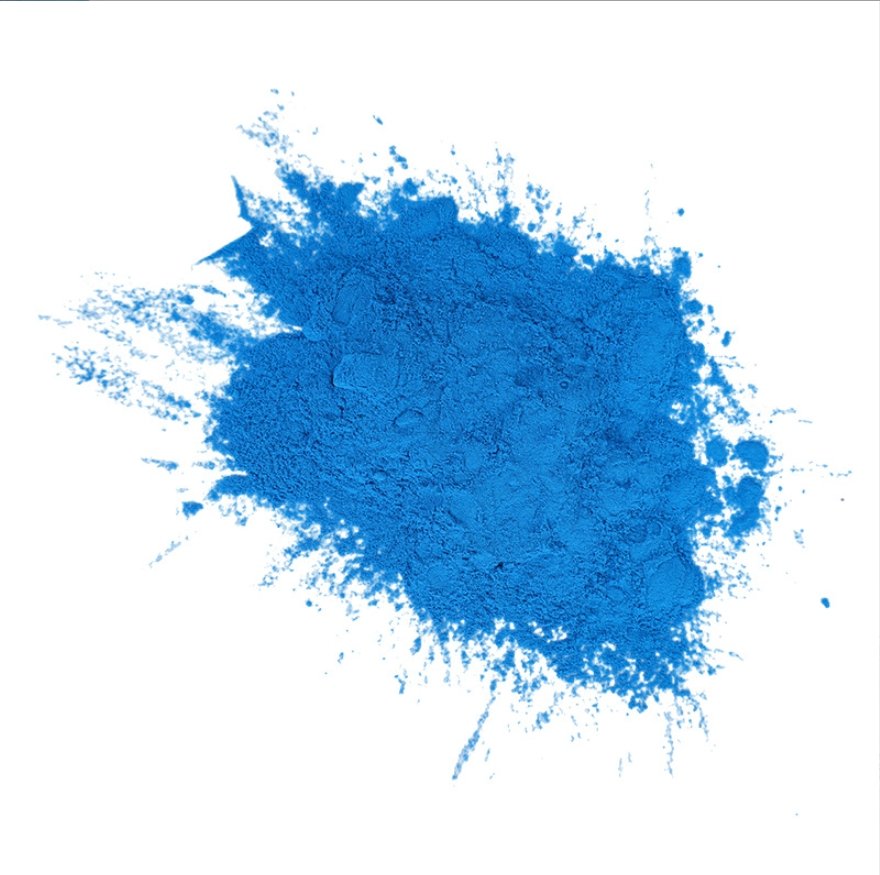

✅ **Uniform Particle Size** – High-quality powder has a consistent particle size (10-100 microns) for **smooth application and even coverage**.

✅ **Free-Flowing Powder** – Should not clump or cake together; poor flowability leads to uneven coating.

✅ **Minimal Moisture Absorption** – Quality powders are **dry and fluffy**, not sticky or damp.

### **2. Application Performance**

✅ **Good Electrostatic Charging** – The powder should evenly attract to the grounded surface during spraying. Poor charging can cause **uneven thickness or defects**.

✅ **Smooth & Even Coating** – After spraying, check if the powder lays **uniformly** without **bubbling, pinholes, or orange peel texture** (unless intentional).

✅ **Efficient Coverage** – High-quality powder provides **better coverage with less material**, reducing waste.

### **3. Curing & Adhesion Tests**

✅ **Curing Consistency** – After baking, the coating should be **fully cured**, not over- or under-cured (which can cause brittleness or poor adhesion).

✅ **Cross-Hatch Adhesion Test** – Use a blade to make a grid on the coated surface, apply adhesive tape, and pull it off. **High-quality powder should not peel or flake**.

✅ **Bend & Impact Resistance** – A properly cured coating should not crack when the substrate is bent or impacted.

### **4. Durability & Resistance Tests**

✅ **Scratch & Abrasion Resistance** – Rub a hard object (e.g., coin or metal) against the surface. **Good quality powder should resist scratching and chipping**.

✅ **Chemical Resistance** – Expose the coating to solvents, acids, or alkaline solutions. High-quality powders resist corrosion and degradation.

✅ **UV & Weather Resistance** – Place coated samples under **UV light or outdoor conditions** for some time. Poor-quality powders fade or degrade quickly.

### **5. Manufacturer & Certification**

✅ **Reliable Supplier** – Choose reputable brands with consistent product quality.

✅ **Certifications & Standards** – Look for ISO, RoHS, REACH, and ASTM certifications, ensuring environmental and performance compliance.

✅ **Batch Consistency** – The powder should maintain **color, texture, and performance** across different production batches.

Would you like recommendations for a specific **application or industry**?

electrostatic handheld sprayer

electrostatic mist sprayer

electrostatic orchard sprayer

electrostatic paint spray system

electrostatic paint sprayer cost

electrostatic paint sprayer diagram

electrostatic paint sprayer for rent

electrostatic paint sprayer graco

electrostatic paint sprayer how it works

electrostatic paint spraying systems

electrostatic painting vs spray painting